The electric flange butterfly valve is composed of an electric actuator and a flange butterfly valve. According to different working modes and working conditions, it can be divided into switch control type and intelligent adjustment type (4~20mA analog signal control). The sealing forms include soft seal and hard seal. Working through the electric actuator, the rotating valve rod drives the disc plate to open and close within the range of 0-90 °. The structural performance of the electric flange butterfly valve is better than that of the wafer type butterfly valve, and the pressure resistance is generally high. The electric flange butterfly valve is recommended for the working conditions with the diameter of more than DN600.

Performance characteristics of electric flange butterfly valve:

1. An automatic butterfly valve that can be remotely controlled has the characteristics of a flange butterfly valve, and can be equipped with a wide range of butterfly valves;

2. The power supply is the driving energy of the electric butterfly valve. It has a wide range of power sources and applications, which saves human resources and is more efficient;

3. Easy to operate, easy to meet various control requirements, can be achieved by selecting different electric actuators, signal feedback, flow regulation, explosion-proof and other functions;

4. It can realize super miniaturization and mechanical self-locking, and can replace different sealing rings to meet different working conditions.

|

Executive standard of electric flange butterfly valve:

Design specification: GB/T 12238

Structure length: GB/T 12221

Flange connection: GB/T 9113

Test and inspection: GB/T 13927

Different electric actuators are selected according to different process requirements:

Switch type, signal feedback type, explosion-proof type, regulating type, etc

|

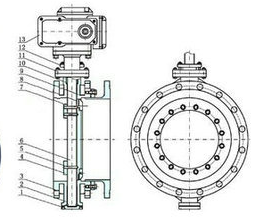

Structure diagram of electric flange butterfly valve

|

Operating principle of electric flange butterfly valve:

The electric flange butterfly valve uses the electric actuator to input a standard signal of 0-10 mA, and the motor unit drives the angular torque of the gear worm to drive the disc to rotate. When the valve is in the fully open position, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body, so the pressure drop generated through the valve is very small, so it has good flow control characteristics. The electric flange butterfly valve has two sealing types: elastic seal and metal seal. For elastic sealing valve, the sealing ring can be embedded on the valve body or attached to the periphery of the butterfly plate. Metal sealed valves generally have longer service life than elastic sealed valves, but it is difficult to achieve complete sealing. The metal seal can adapt to higher working temperature, while the elastic seal has the defect of temperature limitation. If the electric flange butterfly valve is required to be used as flow control, the main thing is to correctly select the size and type of the valve.