The electric three eccentric butterfly valve adopts a three-dimensional eccentric structure, which has the advantages of strong applicability, small torque force, less friction, good sealing performance, etc. It is mainly composed of flange or wafer type three eccentric butterfly valve and electric actuator. When the electric three eccentric butterfly valve is opened, the disc plate immediately separates the sealing surface of the valve seat, reducing the friction and interference with the sealing surface, and greatly improving the service life of the butterfly valve. Moreover, the disc plate and the sealing surface of the valve seat of the electric three eccentric butterfly valve are made of stainless steel, so that the anti-corrosion, temperature resistance, pressure resistance and wear resistance of the butterfly valve can be reliably guaranteed. It is a high-performance energy-saving electric butterfly valve.

Application of electric three eccentric butterfly valve:

The electric triple eccentric butterfly valve has the dual advantages of metal sealing and elastic sealing. It has excellent sealing performance both at low temperature and high temperature. It is also widely used in some fields of high temperature, high pressure, strong corrosion, etc., mainly used in petroleum, chemical industry, power, metallurgy, steel, paper making, medicine, food, textile, light industry and other industries.

Performance characteristics of electric three eccentric butterfly valve:

1. There are electric wafer type three eccentric butterfly valve and electric flange three eccentric butterfly valve, which can meet the requirements of pipelines with different connection modes.

2. The sealing performance is reliable, and the service life is long. The three-dimensional eccentric structure is adopted. There is very little friction between the butterfly valve and the valve body when it is opened and closed.

3. Different valve body materials and sealing rings can be used for different temperatures, pressure levels, corrosion resistance and other media;

4. Three eccentric structure, with the sealing function of closing more tightly, is flexible in operation, and is not affected by high and low media pressure. 5. The electric three eccentric butterfly valve can adjust the butterfly plate seal ring to close to the valve seat, restore the original sealing performance, and greatly improve the service life.

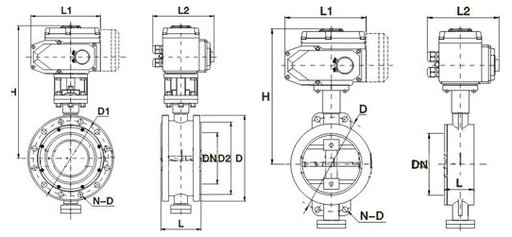

Outline structure of electric three eccentric butterfly valve:

Structure Diagram of Electric Flange Three Eccentric Butterfly Valve Structure Diagram of Electric Wafer Three Eccentric Butterfly Valve