The electric soft seal butterfly valve is generally of medium linear structure, mainly composed of soft seal butterfly valve and electric actuator, and can be divided into flange type and wafer type according to different connection modes. Its sealing form adopts sealing structure and has good sealing performance (up to zero leakage). The sealing materials are various rubbers, polytetrafluoroethylene, etc. Electric soft seal butterfly valves are generally used in normal temperature environments with a temperature of ≤ 200 ℃ and a nominal pressure of ≤ 1.6MPa, as well as in low and medium pressure places. Due to the limitation of structural characteristics, they are not suitable for industries such as high temperature, high pressure and wear resistance. It is widely used in water treatment, environmental protection, petroleum, chemical and other pipelines as flow regulating and intercepting media.

Performance characteristics of electric soft seal butterfly valve:

1. Novel and reasonable design, unique structure, light weight, quick opening and closing.

2. Small operating torque, convenient operation, labor saving and dexterous.

3. It is divided into electric wafer type soft seal butterfly valve and electric flange soft seal butterfly valve.

4. The sealing elements can be replaced, and the sealing performance is reliable to achieve zero leakage of two-way sealing.

5. The sealing material is aging resistant, corrosion resistant and has a long service life

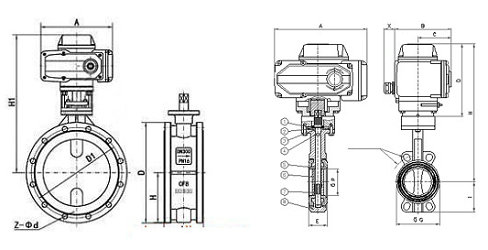

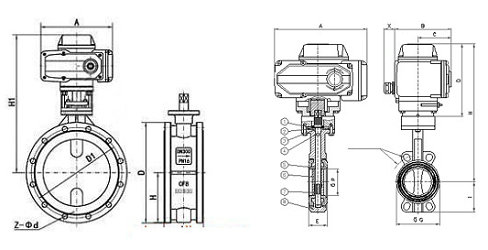

Electric flange soft seal butterfly valve structure Electric wafer type soft seal butterfly valve structure

Difference between electric soft seal butterfly valve and electric hard seal butterfly valve:

1. Soft sealing butterfly valves are mostly of medium line type, while hard sealing butterfly valves are mostly of single eccentric, double eccentric and triple eccentric structure.

2. Soft seal is used in normal temperature environment. Hard seal can be used in low temperature, normal temperature, high temperature and other environments.

3. Soft seal is used for low pressure - normal pressure, and hard seal can also be used for medium and high pressure.

4. The sealing performance of soft sealing and tri eccentric hard sealing butterfly valves is relatively good, and tri eccentric butterfly valves can maintain good sealing under high pressure and high temperature environment.

Advantages and disadvantages of electric soft seal butterfly valve and electric hard seal butterfly valve:

The soft seal butterfly valve has the advantages of good sealing performance and the disadvantages of easy aging, wear and short service life.

Hard sealing butterfly valve has a long service life, but its sealing performance is relatively worse than that of soft sealing butterfly valve.

Soft sealing butterfly valves are suitable for working conditions of water treatment, light industry, chemical industry and other industries at normal temperature and pressure. Hard sealing butterfly valves are mostly used for heat supply, gas, oil, acid and alkali and other high-temperature and high-pressure environments.