The electric regulating ball valve is equipped with a built-in servo system, which can control the operation by inputting 4-20mA signal and 220VAC power supply without additional servo amplifier. The electric V-shaped regulating ball valve is equipped with a special V-shaped notch, which can not only cut off the fiber to prevent jamming, but also form a different V-shaped angle with the valve seat channel, realizing accurate adjustment of various parameters of pipeline media, It is suitable for various viscous media such as pulp or fiber, which can effectively ensure the flow of the pipeline and prevent the ball valve core from being stuck.

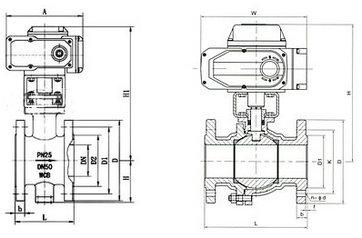

Structure diagram of electric regulating ball valve:

Performance index of electric regulating ball valve:

Control precision: 0.1% - 3.0% (adjustable through U4 parameter)

It can be connected to feedback signal of electric actuator: potentiometer 500 Ω - 10K Ω

External control signal (DC) can be received: 4-20mA (1-5V, 0-10V, switching value, etc. customized before delivery)

Input impedance: 250 Ω;

By modifying U1 parameters, you can set: ① DRTA/forward action, RVSA/reverse action mode ② "Interrupt" mode when the input signal is interrupted - OPEN, STOP, SHUT

Optional: ① SCR output (AC, 600V, 25A) ② Relay output (AC, 250V, 10A) ◆ Specify when ordering

Output actuator position signal: low drift output 4-20 mADC corresponding actuator is fully closed to fully open, signal is completely isolated from input (photoelectric isolation), output load ≤ 500 Ω

Ambient temperature: 0-70 ℃, humidity: 35-85%

With overtemperature protection function: when the temperature in the positioner shell is ≥ 70 ℃, the positioner stops the on-off control of the actuator, and the action range of the actuator corresponding to the input signal can be calibrated freely by pressing the key (generally calibrated as the fully closed and fully open positions of the electric actuator)