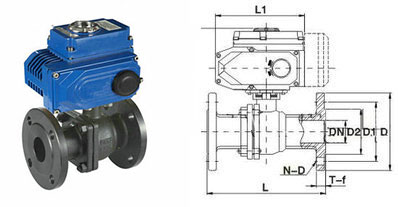

Electric carbon steel ball valve (Q941F electric ball valve) is mainly composed of cast steel flange ball valve and electric actuator. The valve body is made of silica sol precision casting. The valve seat is made of polymer materials such as polytetrafluoroethylene and aligned polystyrene, with good sealing performance and corrosion resistance. The valve body of the electric cast steel ball valve is a floating straight through structure, and adopts a full bore design, with small flow resistance and large flow volume. It can not only be used as a switch to cut off, but also can adjust and control the pipeline medium. It is suitable for water, steam, oil and other media, and is widely used in water treatment, long-distance pipeline, chemical industry, paper making, environmental protection, water conservancy, power and other industries.

Features of electric carbon steel ball valve:

1. The electric cast steel flange ball valve adopts full bore or reduced bore design, with large flow capacity and no flow resistance when fully opened.

2. Q941F electric ball valve adopts a high platform structure and is directly installed with the actuator. It can be operated by inputting 4-20mA signal and 220VAC power supply.

3. The valve rod is of built-in type, and the shaft shoulder and polytetrafluoroethylene (or reinforced graphite) thrust pad structure prevent the valve rod from blowing out due to the pressure in the pipeline. At the same time, the polytetrafluoroethylene (or reinforced graphite) material reduces the opening and closing torque of the valve, so that the operation is more labor-saving.

4. It has a fireproof and anti-static structure. A conductive spring is set between the valve rod and the valve body and between the valve rod and the ball to avoid ignition of flammable media due to electrostatic ignition. Ensure system security.

5. The electric cast steel ball valve has the advantages of simple connection, compact structure, small size, light weight, small resistance, stable and reliable action, etc.