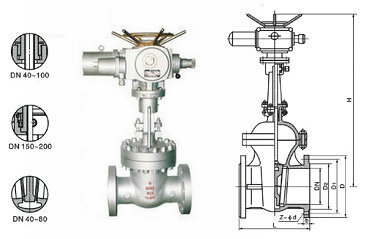

Structural features of electric high-pressure gate valve:

1. The valve adopts pressure self tightening seal or valve body and bonnet gasket seal structure, which is safe and reliable.

2. The valve disc adopts the structure of double gate plates with universal roof in the middle, which can automatically adjust the fitting degree of the valve disc and the sealing surface of the valve seat to ensure the sealing of the valve. This structure is convenient for maintenance and cost saving, and the valve disc has good interchangeability.

3. The sealing surface of valve disc and valve seat is made of cobalt chromium tungsten carbide by plasma spray welding, with high hardness, abrasion resistance, scratch resistance and long service life.

4. The valve rod is made of nitrided steel, with nitrided surface, high hardness, scratch resistance, corrosion resistance and long service life.

5. The electric device is equipped with a torque control mechanism, a field operating mechanism, and a manual and electric switching mechanism.