Product name: Intelligent anti vibration vortex flowmeter

Measuring medium: gas, liquid, steam, heat transfer oil

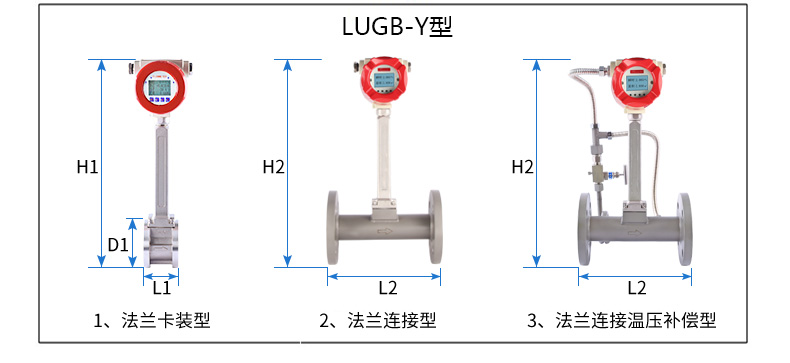

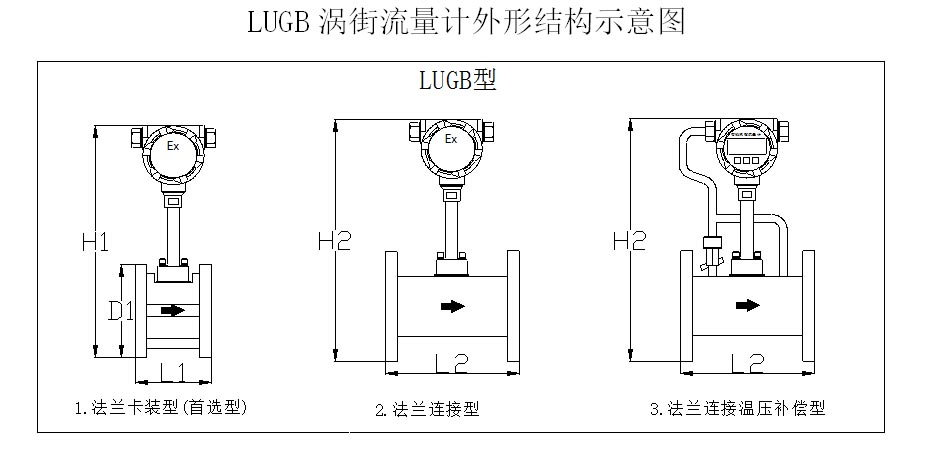

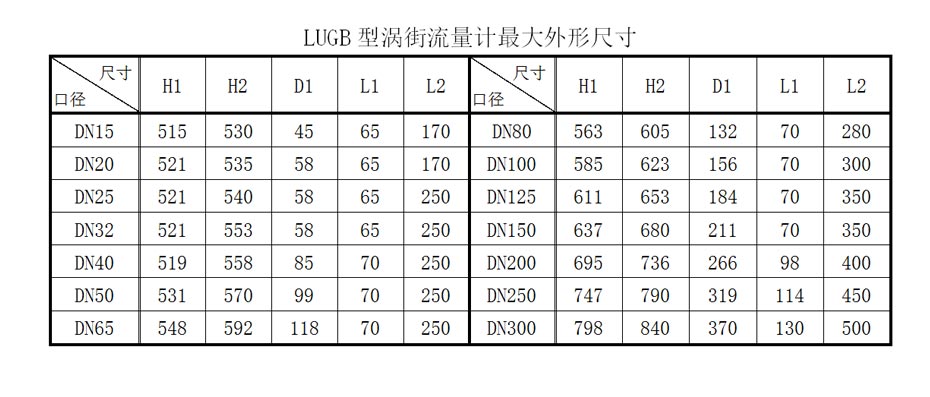

Nominal diameter: DN15-DN300

Output signal: voltage frequency pulse, 4~20mA signal

Communication mode: RS485, HART optional

Working power supply: 24VDC ± 5%, lithium battery 3.6VDC

Nominal pressure: flange clamp type (2.5MPa)

Flange connection type (1.0/1.6/2.5 MPa)

Accuracy class: 1.5 (gas), 1.0 (liquid)

Medium temperature: - 40 ℃~+260 ℃, - 40 ℃~+300 ℃

Protection grade: IP65

L Selection of installation site and environment

1. Try to avoid strong power equipment, high-frequency frequency conversion equipment and strong power switch equipment;

2. Try to avoid the influence of high temperature heat source and radiant heat source; Sun shading and rain proof measures shall be taken for outdoor installation;

3. Try to avoid vibration places and strong corrosive environments; At the same time, easy installation and maintenance shall be considered;

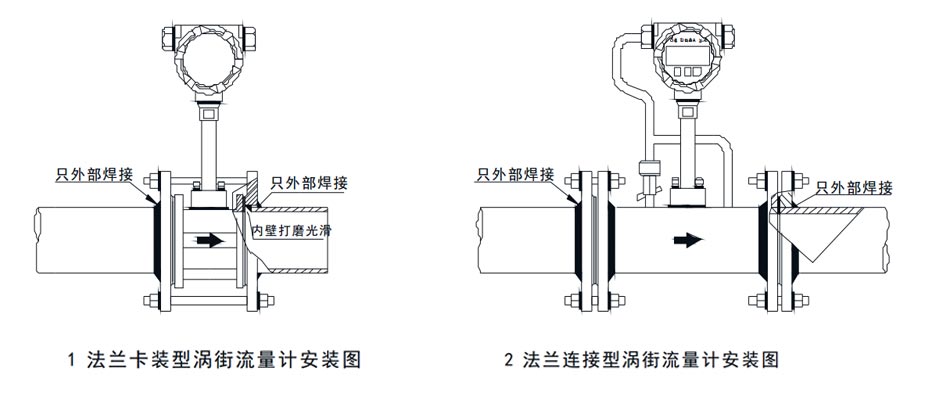

L Reasonable and correct installation position

1. Try to avoid selecting pipes with strong vibration at the installation position, or vibration reduction measures must be taken, such as installing shock absorption nipples;

2. The flowmeter can be installed horizontally, vertically and obliquely. When measuring liquid, it must be ensured that the fluid flows from low to high;

When measuring gas, the flow direction is unlimited;

When measuring steam or high-temperature gas, the support of the meter body shall be installed at 45 ° with the vertical direction as far as possible;

L Requirements for straight pipe section

In order to measure accurately, there must be enough straight pipe sections at the upstream and downstream of the flowmeter, and there should be no components at the upstream that affect the fluid velocity distribution

L Grounding requirements

When installing the flowmeter, the meter body shall be reliably grounded. If the field pipeline does not have grounding conditions, a separate reliable ground wire shall be made to connect with the grounding terminal of the instrument housing.