Pneumatic rubber lined butterfly valve (pneumatic rubber environment-friendly anti-corrosion butterfly valve) refers to vulcanizing the rubber and the valve body of the butterfly valve into a whole through high temperature. It is generally divided into flange type and wafer type according to the connection mode, and the sealing structure with different performance (full rubber lined butterfly valve, semi rubber lined butterfly valve) can be selected according to the use requirements of different working conditions, To ensure the normal use of pneumatic rubber lined butterfly valve in different applications. Pneumatic rubber lined butterfly valve is not only anti-corrosion, wear-resistant, non-toxic, mildew proof and other characteristics, but also has excellent sealing performance. With the application of chemical anti-corrosion synthetic rubber in butterfly valve, the use of rubber lined pneumatic butterfly valve has been constantly increasing.

Application range of pneumatic rubber lined butterfly valve:

Rubber lined pneumatic butterfly valve is applicable to the transmission of liquid and gas (including steam) and other media in various types of industrial pipelines, as well as the use of weakly corrosive fluid media. It can be used for on-off two position control or medium flow adjustment. The working temperature generally does not exceed 180 ℃, and the nominal pressure is ≤ 1.6MPa. It is widely used in food, medicine, chemical industry, petroleum, power, textile, paper and other places.

Performance characteristics of pneumatic rubber lined butterfly valve:

1. The rubber lining is adopted without pin, which ensures the complete isolation of medium and metal, and improves the reliability of the product.

2. The sealing surface has good abrasion resistance (the abrasion resistance of rubber is seven times that of copper).

3. It can be installed in any position and is convenient for maintenance.

4. The sealing elements can be replaced, and the sealing performance is reliable to achieve zero leakage of two-way sealing.

5. The rubber material has no toxicity, and is antibacterial and mold resistant. The product price is one third of that of stainless steel valves.

|

Standard specification for pneumatic rubber lined butterfly valve:

Design and manufacturing standard: GB/T 12238-2008

Structure length standard: GB/T 12221-2005

Connecting flange standard: GB/T 9113

Pressure and temperature class: GB/T 12224-2005

Test and inspection standard: GB/T 13927-2008

Material of pneumatic rubber lined butterfly valve parts:

|

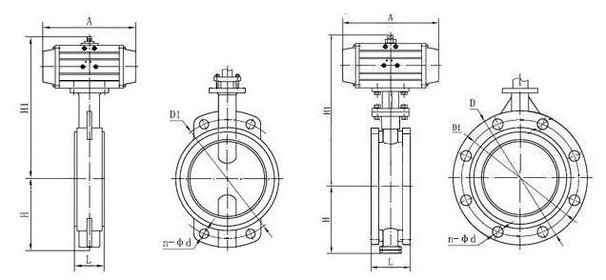

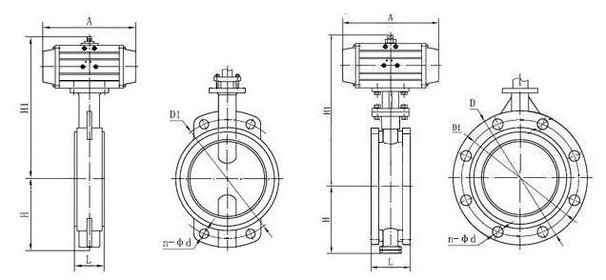

Pneumatic rubber lined butterfly valve (wafer type) Pneumatic rubber lined butterfly valve (flange type) |

Valve body: cast iron, ductile iron, carbon steel, stainless steel

Butterfly plate: cast iron, ductile iron, carbon steel, stainless steel completely covered with rubber or fluoroplastic

Valve rod: carbon steel, nickel phosphorus plated, stainless steel

Seat sealing ring: natural rubber NR, neoprene CR, nitrile rubber NBR, EPDM, fluororubber FKM

Operating temperature of sealing ring: nitrile rubber X ≤ 80 ℃; Wear resistant rubber X6 ≤ 150 °; Neoprene ≤ 120 degrees; Fluoroelastomer X7 ≤ 150 degrees;