|

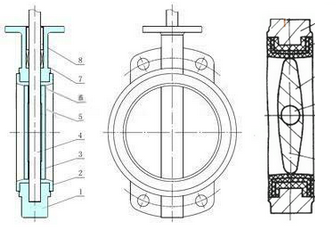

Nominal diameter: DN50~1200 (mm)

Nominal pressure: PN0.6, 1.0, 1.6, 2.5MPa

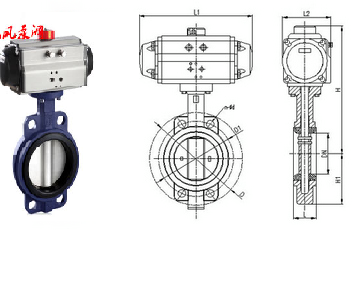

Connection type: wafer type Flange connection

Structure type: central line structure

Flow characteristics: approximate quick opening type

Action range: 0~90 °

Leakage: 10-4 of Kv according to GB/T4213-92, soft seal: zero leakage

Basic error: with positioner: less than ± 2% of full stroke

Return difference: with positioner: less than ± 2% of full stroke

Equipped with actuator: GT, AT, AW series single double acting pneumatic actuator

Control mode: switch type (switch two position control), regulating type (4~20mA control)

|