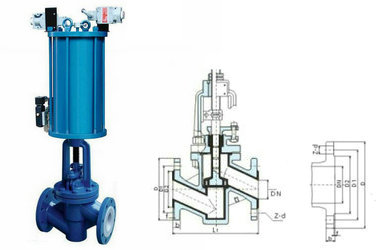

The pneumatic fluorine lined stop valve (J641F46) has the characteristics of compact structure, high strength, strong corrosion resistance, etc. It is specially used to control various anti-corrosion valves containing corrosive media. The valve chamber is entirely lined with anti-corrosion fluorine materials, and is suitable for pipelines with various concentrations of corrosive gases, liquids and solution media with temperatures ranging from - 10 ℃ to 150 ℃. The valve seat of the pneumatic fluorine lined globe valve uses integral polymer as the sealing material, which has excellent sealing performance in a wide range of temperature and pressure; The valve whose opening and closing parts (valve disc) are driven by the valve stem and move up and down along the central axis of the valve seat is mainly used to connect or cut off the medium in the pipeline, but cannot be used for throttling.

Features of pneumatic fluorine lined stop valve:

1. The pneumatic fluorine lined stop valve is simple in structure, convenient in installation and maintenance, small in working stroke, and adopts a top-down flow structure.

2. J641F46 pneumatic stop valve adopts lining process, and the lining material is generally FEP (F46), PCTFE (F3) and other fluoroplastics, which can be applied to pipelines with various concentrations of sulfuric acid, hydrochloric acid, hydrofluoric acid, aqua regia, various organic acids, strong acids, strong oxidants and other corrosive media.

3. The flange fluorine lined stop valve has good sealing performance. The adhesive of sealing material can make the lining adhesive have a strong affinity with the pipe wall. It has good anti rust and anti scaling performance and long service life.