PQ640H pneumatic eccentric hemisphere valve is characterized by non friction when opening and closing, non wearing seal, small opening and closing torque, etc. It uses the hemisphere to rotate around the eccentric axis to control the pipeline medium. In the process of opening and closing, there will be no friction between the sphere and the sealing surface of the valve seat, which reduces the wear of the seals and greatly improves the service life. Since the structural principle of pneumatic eccentric hemisphere valve is very similar to the operation form of three eccentric butterfly valve, Gu has called the eccentric hemisphere valve a butterfly valve with a spherical disc.

Features of pneumatic eccentric hemisphere valve:

1. The ball of PQ640H pneumatic eccentric ball valve is completely separated from the valve seat, which eliminates the wear of the sealing ring and overcomes the problem of the wear of the traditional ball valve seat and the ball sealing surface. The non-metallic elastic material is embedded in the metal seat, and the metal surface of the valve seat is well protected.

2. The V-notch of the pneumatic eccentric ball valve has the cutting function, which can cut off the sundries (branches, textile bags, etc.) in the medium when closing to ensure the normal opening and closing of the valve.

3. 2. The hemispherical bimetal of the valve is welded with different alloys on the base metal, and the valve seat is also welded with corresponding surfacing. After special treatment, the sealing surface is assembled into anti-corrosion, wear-resistant, high-strength and other types to meet the needs of different occasions.

4. The pneumatic eccentric rotary valve is especially suitable for mud and media containing fiber, as well as media containing micro suspended solids. It is widely used in petroleum, chemical, paper making, sewage treatment and other pipelines for on-off or flow regulation.

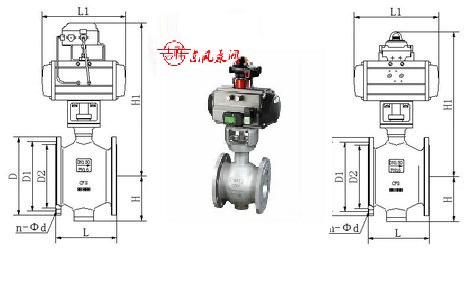

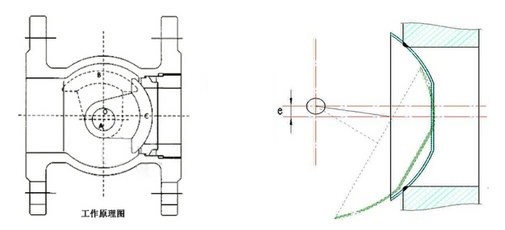

Principle description of pneumatic eccentric hemisphere valve (figure):

The offset dimension between the center line of the half sphere and the center line of the valve stem of the pneumatic eccentric hemisphere valve is offset from the center line of the valve seat. When the valve is fully opened, the sphere and the valve seat are completely disengaged, and there is a certain gap. The radius of gyration is divided into long radius and short radius. The tangent line of the rotation track in the long radius will form a θ Angle, when the valve is opened and closed, the hemisphere has a gradual separation and gradual extrusion effect on the valve seat surface, thus reducing the mechanical wear and scratches between the valve seat and the hemisphere during opening and closing, and improving the service life.