The pneumatic explosion-proof ball valve actuator can be divided into single action and double action according to the different action forms. The single action type is automatically reset by the spring. Its unique advantage is that the ball valve will automatically return to the open or closed state in case of mechanical failure or no air supply. The double acting switch action is driven by the air source; That is, the ventilation is on, the ventilation is off, and the ventilation is cut off and kept in place.

Optional accessories of explosion-proof pneumatic ball valve:

Actuator model: GT, SR, ST, AT, AW series single and double acting pneumatic actuator

Gas supply pressure: 0.4~0.7MPa

Air source interface: G1/4 ", G1/8", G3/8 ", G1/2"

Ambient temperature: - 30~+70 ℃

Action form:

Single acting actuator: air to close (B) - valve position open (FO) in case of air loss; Air to open type (K) -- valve position closed in case of loss of air (FC)

Double acting actuator: air to close (B) - valve position is kept (FL) in case of loss of air; Air to open type (K) -- valve position is kept (FL) in case of loss of air

Accessories available:

Positioner, explosion-proof solenoid valve, air filter pressure reducer, retaining valve, travel switch, valve position transmitter, handwheel mechanism, etc

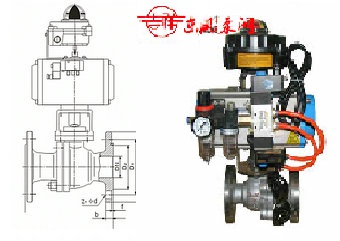

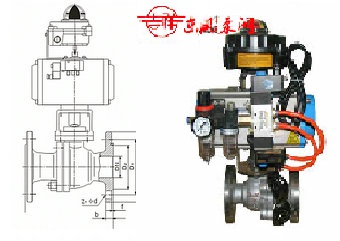

Structural Drawing of Explosion proof Pneumatic Ball Valve