The pneumatic soft seal gate valve adopts the first-class rubber vulcanization technology to carry out the overall internal and external rubber, so that the vulcanized valve can ensure accurate geometric dimensions, and the rubber and the gate valve are firmly connected, not easy to fall off and have good elastic memory. Compared with the traditional gate valve, the Z645X elastic seat seal gate valve has the same flat bottom design as the water pipe at the bottom, which is not easy to cause debris deposition and make the fluid unobstructed. The traditional gate valve is often unable to close tightly and causes water leakage due to foreign matters such as stones, wood blocks, cement, paper scraps, sundries and other sludge accumulated in the bottom groove of the valve after the pipe is washed with water, while the soft seal gate valve does not.

Features of pneumatic soft seal gate valve:

1. The valve body is coated with powder epoxy resin, which can prevent the valve body from corrosion and rust, and can be used in the sewage system, so it is not easy to break. In the past, traditional cast iron gate valves were often broken due to the impact, collision or overlap of foreign objects.

2. The use of three "O" ring seal ring design can reduce the friction resistance when switching, greatly reduce water leakage, and can replace the seal ring without stopping water construction.

3. Since the interior of the valve body is coated with non-toxic epoxy resin, the internal and external surfaces of the gate valve are completely covered with rubber, so that rust water or corrosion will not occur, and it can be used for drinking.

4. The valve body is made of precision casting, and the precise geometric dimensions enable the sealing of the valve without any finish machining in the north of the valve body.

5. The body is made of spheroidal graphite casting, and its weight is 20% to 30% less than that of traditional gate valves, which is convenient for maintenance.

Standard specification for pneumatic soft seal gate valve:

General Purpose Valves Flanged Iron Gate Valves GB/T 12232-2005

General Requirements for Steel Valves (GB/T 12224-2005)

Steel Flat Gate Valves for Pipeline (JB/T 5298-91)

Inspection and Test of Valves JB/T 9092-1999

Technical parameters of pneumatic soft seal gate valve:

Nominal diameter: 50~1200mm

Nominal pressure: 1.0~2.5MPa

Connection mode: flange type

Operating temperature: 0~80 ℃

Control mode: pneumatic control

Applicable media: water, oil, gas, etc

|

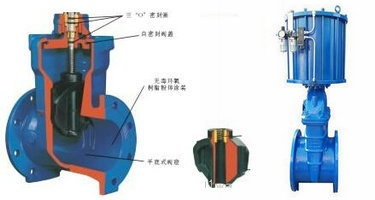

Structure diagram of soft seal elastic seat gate valve

|