The pneumatic knife gate valve is composed of a stainless steel wafer type knife gate valve and a pneumatic actuator. The bottom of the gate plate is a knife shaped oblique notch, which has a good shearing effect, so that the valve will not be blocked by media when it is closed, and can scrape off the adhesive on the sealing surface, automatically remove debris, which is most suitable for slurry, powder, fiber and other fluids that are difficult to control for flow opening and closing. The pressure range of PZ673H pneumatic wafer type knife gate valve is generally within 1.0MPa, and the temperature is below 120 ℃. Special materials can be used instead of high temperature, which is widely used in papermaking, petrochemical, mining, drainage, food and other industries. There are a variety of valve seats to choose from, and electric or pneumatic actuators can be equipped according to the needs of field control to realize the automatic operation of valves.

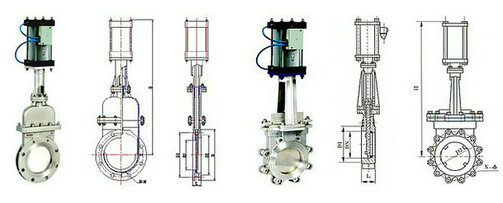

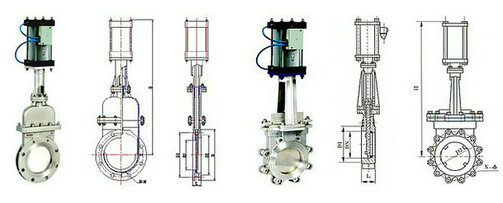

Structure Diagram of Pneumatic Clamping Knife Gate Valve Structure Diagram of Pneumatic Lug Knife Gate Valve

Structure Diagram of Pneumatic Clamping Knife Gate Valve Structure Diagram of Pneumatic Lug Knife Gate Valve

Performance characteristics of pneumatic knife gate valve:

1. Double clip structure, small size and light weight; The completely open channel can prevent the medium from depositing in the valve.

2. In the process of opening and closing, the ram and sealing surface adopt special design, with less friction and durability.

3. The upper seal adopts the upper cover structure, so that the upper seal is changed from a large rectangular seal to a small circumferential seal, and the sealing performance is greatly improved.

4. After the sealing device is installed on the top of the hand wheel, all the moving parts of the valve can be kept in a closed state, and the screw rod drive of the gate and valve rod will not be jammed due to the drying of lubricating oil. 5. The ram has the function of knife switch, which can effectively cut off various sundries in the medium