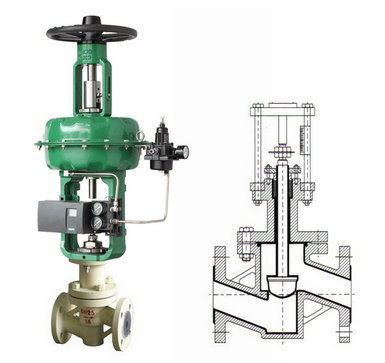

ZJHPF46 pneumatic fluorine lined regulating valve is mainly composed of multi spring pneumatic membrane actuator and corrosion resistant straight through single seat valve, which is specially used in corrosive and permeable medium pipelines or pipelines in the chemical industry, with good sealing performance and small leakage. As the parts contacting the medium of the valve are all made of high-temperature molding or high-pressure injection molding process, fully lined corrosion-resistant and anti-aging fluoroplastics FEP (F46), PFA, Po or other lining materials, and polytetrafluoroethylene bellows seals can also be optionally installed, so that the control valve can be widely used in chlor alkali, chemical, petroleum, metallurgy, medicine, power station and other industries to realize the control of wet chlorine Process control of hydrochloric acid, strong alkali, toxic, harmful and other strong corrosive media.

Features of pneumatic fluorine lined control valve:

1. Corrosion resistance: the inner cavity of valve body, valve core and valve stem are lined with FEP (F46) 2.5~3mm thick, which is resistant to salt, acid and alkali and strong corrosion.

2. Good sealing performance: PTFE bellows and packing are used for double sealing at the stuffing box to ensure no leakage.

3. Small leakage: because the valve core and valve seat are soft sealing structures, the leakage is lower than the level IV leakage standard in the national standard GB/T4213.

4. The actuator is a small multi spring actuator with small size and light weight. High adjustment accuracy.