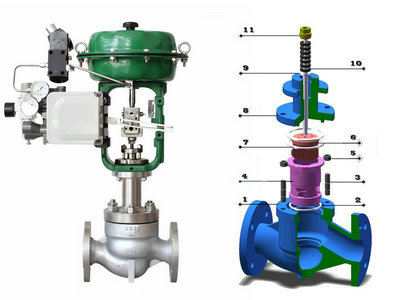

ZJHM pneumatic diaphragm sleeve control valve is a high performance and large capacity control valve product. With sleeve guidance, it has large guiding area and good stability. It can quickly replace the valve internals online, with high maintenance efficiency, saving manpower and time. The pneumatic diaphragm sleeve regulating valve is widely used because of its good stability and simple maintenance. The pressure balanced valve core eliminates most of the static unbalanced force on the valve disc, and has a certain damping effect, which can reduce the vibration caused by fluid flow. It is especially suitable for situations where the leakage is not high and the pressure difference between the front and back of the valve is large!

Features of pneumatic diaphragm sleeve regulating valve:

1. Balanced valve core is adopted, with small unbalanced force, large allowable pressure difference and stable operation.

2. The large guiding surface of the valve core can improve the oscillation caused by vortex and impact, and reduce damage.

3. The noise is about 10dB lower than that of ordinary single and double seat control valves.

4. Simple structure, easy assembly, disassembly and maintenance.

Principle of pneumatic diaphragm sleeve regulating valve:

The pneumatic diaphragm sleeve regulating valve is an important execution unit of the instrument in the automatic control system. The electro pneumatic valve positioner is used to receive the current signal (0-10mA DC or 4-20mA DC) input from the control system, powered by the electrical signal and compressed air. The regulator converts the compressed air into the air source pressure signal input and output, thus changing the valve opening displacement, Achieve accurate regulation and control of process parameters such as pipeline fluid medium flow, pressure, temperature and liquid level!