|

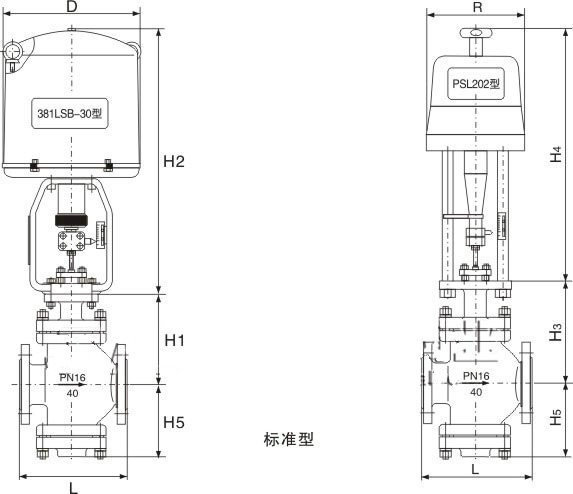

Overall dimensions and weight Unit: mm |

| Nominal diameter |

twenty-five |

thirty-two |

forty |

fifty |

sixty-five |

eighty |

one hundred |

one hundred and twenty-five |

one hundred and fifty |

two hundred |

| L |

PN16/40 |

one hundred and eighty-five |

two hundred |

two hundred and twenty |

two hundred and fifty |

two hundred and seventy-five |

three hundred |

three hundred and fifty |

four hundred and ten |

four hundred and fifty |

five hundred and fifty |

| PN64 |

two hundred |

two hundred and ten |

two hundred and thirty-five |

two hundred and sixty-five |

two hundred and ninety-five |

three hundred and twenty |

three hundred and seventy |

four hundred and forty |

four hundred and seventy-five |

five hundred and seventy |

| D |

|

two hundred and fifty-five |

two hundred and fifty-five |

two hundred and fifty-five |

two hundred and fifty-five |

two hundred and fifty-five |

two hundred and fifty-five |

two hundred and fifty-five |

three hundred and ten |

three hundred and ten |

three hundred and ten |

| R |

|

one hundred and seventy-seven |

one hundred and seventy-seven |

one hundred and seventy-seven |

one hundred and seventy-seven |

one hundred and seventy-seven |

one hundred and seventy-seven |

one hundred and seventy-seven |

two hundred and twenty-six |

two hundred and twenty-six |

two hundred and twenty-six |

| H1 |

PN16/40 |

one hundred and fifty-five |

one hundred and seventy-five |

one hundred and eighty |

two hundred |

two hundred and thirty-five |

two hundred and fifty |

two hundred and sixty |

three hundred and thirty |

three hundred and fifty |

four hundred and twenty |

| PN64 |

one hundred and sixty-five |

one hundred and eighty-five |

one hundred and eighty-five |

two hundred and five |

two hundred and forty-five |

two hundred and fifty-five |

two hundred and seventy |

three hundred and thirty-five |

three hundred and sixty-five |

four hundred and thirty |

| H3 |

PN16/40 |

one hundred and seventy-one |

one hundred and ninety-five |

two hundred |

two hundred and twenty |

two hundred and sixty-two |

two hundred and seventy-seven |

two hundred and eighty-seven |

three hundred and fifty-seven |

three hundred and seventy-seven |

four hundred and forty-seven |

| PN64 |

one hundred and eighty-one |

two hundred and five |

two hundred and five |

two hundred and twenty-five |

two hundred and seventy-two |

two hundred and eighty-two |

two hundred and ninety-seven |

three hundred and sixty-two |

three hundred and ninety-two |

four hundred and fifty-seven |

| H2 |

|

three hundred and seventy-three |

four hundred and ninety-five |

four hundred and ninety-five |

four hundred and ninety-five |

seven hundred |

seven hundred |

seven hundred |

seven hundred and twenty-five |

seven hundred and twenty-five |

seven hundred and twenty-five |

| H4 |

|

four hundred and fifty-nine |

four hundred and fifty-nine |

four hundred and fifty-nine |

four hundred and fifty-nine |

five hundred and twenty |

five hundred and twenty |

five hundred and twenty |

five hundred and seventy |

five hundred and seventy |

five hundred and seventy |

| H5 |

PN64 |

one hundred and twenty |

one hundred and twenty |

one hundred and forty |

one hundred and forty-five |

one hundred and ninety |

two hundred and ten |

two hundred and twenty |

two hundred and seventy |

two hundred and eighty |

three hundred and twenty |

weight

(KG) |

PN16/40 |

sixteen |

nineteen |

twenty-two |

twenty-three |

thirty-nine |

fifty |

fifty-nine |

eighty |

eighty-seven |

one hundred and fifteen |

| PN64 |

twenty-one |

twenty-four |

thirty-one |

thirty-three |

forty-nine |

seventy-five |

ninety-two |

one hundred and twenty-nine |

one hundred and thirty-seven |

one hundred and seventy |